Nail interlock is a vital technique in various construction projects. According to expert John Smith, "Nail interlock enhances stability and strength in wooden structures." This method involves interlocking nails that provide additional support.

In practical applications, nail interlock is crucial for framing and flooring. It allows for precise alignment and secures materials together effectively. However, many contractors overlook the nuances of this technique, impacting the overall structure's integrity.

Understanding nail interlock can significantly elevate construction quality. Yet, it often requires meticulous attention to detail. Proper training and awareness of common mistakes are essential. Recognizing these imperfections can lead to better practices in the industry. Nail interlock not only connects materials but also ensures the safety and longevity of buildings.

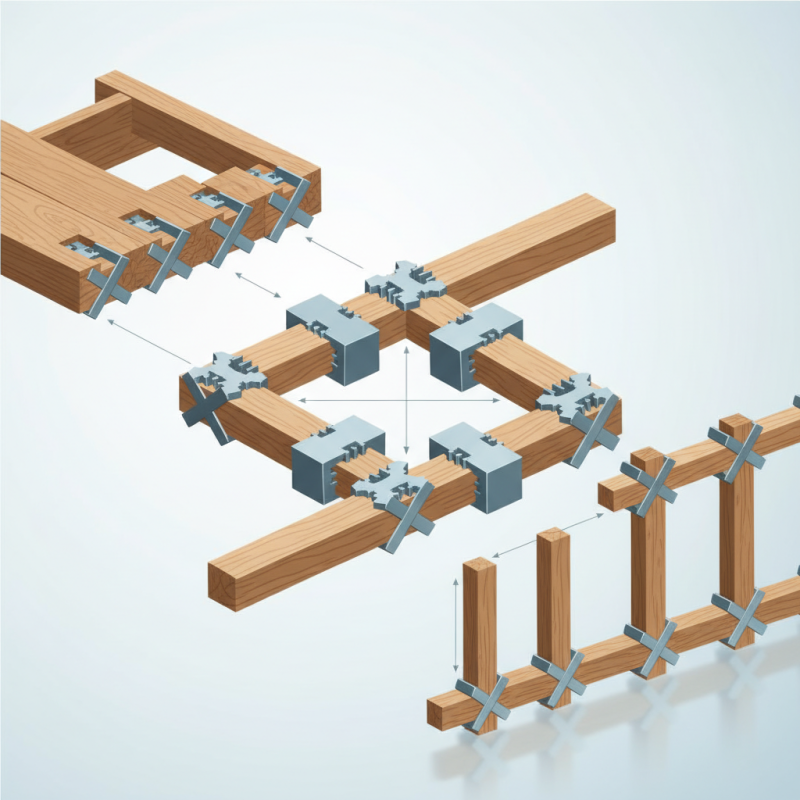

Nail interlock is a significant construction technique. It is essential for enhancing structural integrity. Understanding its definition clarifies its importance in various industries, including construction and manufacturing. This technique involves interlocking nails in multiple layers, creating a stronger bond that resists stress and vibration.

According to industry reports, using nail interlock can improve load capacity by up to 30%. This statistic underscores its value in building applications. Moreover, it reduces the need for additional fastening materials, saving time and cost. The simplicity of the method appeals to builders who seek efficiency and effectiveness.

Tips: Ensure proper alignment during installation. Misalignment can weaken the interlock and compromise integrity. Regular maintenance checks are vital. This practice can prevent unforeseen issues and prolong the structure's lifespan. Remember, even the best techniques require careful attention to detail. Small oversights can lead to long-term consequences in safety and durability.

Nail interlock is an innovative mechanism that optimizes strength in various structures. It allows the connection of materials without traditional fasteners. Instead, nails are interlocked, creating a secure bond. This method often leads to a significant reduction in stress points.

One key benefit of nail interlock is enhanced flexibility. Buildings can better withstand movement and pressure. The interlocking design distributes forces evenly. This reduces the risk of injury during high-stress situations. However, proper alignment is crucial. Misalignment can lead to weak connections, compromising stability.

Tip: Always double-check alignment before securing. This can save time and prevent costly mistakes. Also, consider the materials you use; they should complement each other for optimal results. Testing different combinations can reveal unexpected benefits.

It's essential to understand the limitations of nail interlock. While its benefits are clear, it may not suit every scenario. Over-relying on it can lead to vulnerabilities. Remember, balance is key in any construction approach.

Nail interlock is a technique used in woodworking and construction. It relies on the interlocking of nails to create a secure connection between pieces of material. The strength of this system largely depends on the materials used.

Common materials for nail interlock systems include steel, aluminum, and wood. Steel nails are often favored for their strength and durability. Aluminum offers lightweight options, making it easier to handle. Wood, while not a nail itself, plays a critical role as the connecting element.

When using these materials, consider their properties carefully. Steel nails excel in load-bearing applications. However, they may be prone to rust without proper treatment. Aluminum can corrode but is less likely to do so compared to steel.

Tip: Always check if the material fits your specific project needs.

Sometimes, the alignment of nails can present challenges. Misalignment may weaken the connection, leading to failure. Regularly inspect your work to ensure everything is lined up correctly.

Tip: Take your time during the preparation phase.

Using the right materials and maintaining quality checks ensures a stronger, more reliable nail interlock system.

Nail interlock technology is gaining traction in various industries. This mechanism creates a strong bond between materials. It is particularly useful in construction and woodworking. Builders often use it for better structural integrity. This connection helps in areas that experience stress or movement.

In the automotive industry, nail interlock finds its place. It enhances the durability of components. Vehicles subjected to harsh conditions benefit from this technique. However, its application requires careful consideration of materials. Mistakes in material selection can lead to failure. Additionally, some industries overlook the maintenance of interlocked components.

The furniture sector also utilizes nail interlock for joints. This method offers a seamless appearance. It allows for elegant designs without sacrificing strength. Yet, achieving the perfect balance can be challenging. The craftsmanship needed can be easily overlooked in mass production. Awareness of potential pitfalls remains essential for all users.

Nail interlock is critical in construction, especially in wood framing. This connection method enhances stability and ensures the durability of structures. Performance metrics help assess these connections, revealing their true strength. Studies indicate that interlocked nails can improve shear strength by up to 25%. This increased capacity is essential for earthquake-prone regions.

When examining the performance metrics, we find inconsistencies. Some tests show excellent results, while others yield lower strengths than expected. The discrepancies might arise from variations in nail types, wood species, or moisture levels. A report from the Wood Engineering Institute suggests conducting thorough testing to pinpoint exact limits. Understanding these factors can elevate construction standards.

A deeper dive into connection failures reveals further areas needing reflection. Engineers often overlook the joint angles or wood defects. Misjudging these aspects can compromise the interlock effect. Additional data highlights that up to 15% of failures occur due to improper installation. Awareness of these challenges drives better practices in the field.