Choosing the right rubber air hose can be a daunting task. Industry expert Tom Jenkins once stated, "Selecting a rubber air hose requires understanding your specific needs." This highlights the importance of considering factors beyond just price.

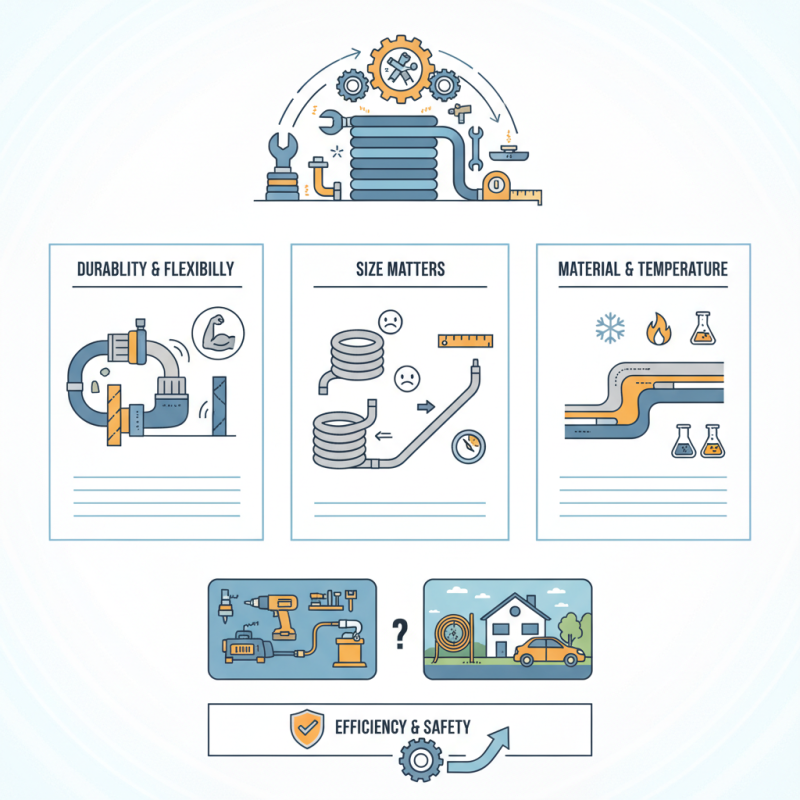

A rubber air hose must be durable and flexible. The right diameter and length are crucial for optimal performance. If a hose is too short, it limits movement. A hose that's too long can lead to air pressure loss. You may also encounter various options in terms of material quality and temperature resistance.

Reflect on your specific usage. Will you use the hose in a workshop, or is it for general tasks at home? Not all rubber air hoses will meet every application. Remember, investing in a high-quality rubber air hose can enhance efficiency and safety. Choose wisely to ensure longevity and reliability.

When choosing a rubber air hose, it’s essential to understand the different types available. There are various options tailored for specific jobs. For instance, some hoses are designed for heavy-duty applications, while others are better suited for light tasks. Heavy-duty hoses usually feature a thicker material. They can withstand higher pressures and are more durable.

Flexibility is another important consideration. Some air hoses remain flexible in low temperatures. Others may become stiff, making them difficult to handle or store. Additionally, hose length varies. Short hoses are easy to manage but may not reach distant areas. Long hoses provide more range but can be cumbersome and prone to tangling.

Another aspect to reflect on is the hose's weight. Lighter hoses are generally easier to carry and maneuver. However, they may sacrifice durability. Consider your working environment as well. A rugged outdoor setting requires a hose that can endure the elements. Pay attention to the fittings as well; they can greatly affect performance. Proper fittings ensure no air leakage, which can save energy. Choosing the right hose thus requires careful thought and planning.

When selecting a rubber air hose, several key factors come into play. The diameter of the hose significantly impacts air flow and pressure. A wider diameter allows for a greater volume of air while a narrower one provides higher pressure. Industry studies suggest that hoses with a diameter of 1/2 inch or more are ideal for high-demand applications. Consider the length as well. Longer hoses might lead to pressure drops, especially if they exceed 50 feet; this is crucial for maintaining efficiency in your tasks.

Tips: Always check the hose’s PSI rating. It tells you how much pressure the hose can handle safely. Picking a hose with a higher rating offers added safety and durability, reducing the risk of bursts during operation.

Also, look for reinforcement materials. Some hoses have additional layers that strengthen them against wear and damage. This is particularly important if the hose will be in contact with abrasive surfaces. The wrong choice can lead to premature failure and costly replacements.

Remember to reflect on your specific usage scenario. Will the hose be exposed to extreme temperatures or chemicals? These factors influence longevity. Oversizing or undersizing can hinder performance. Always reassess your needs before finalizing your choice.

When selecting a rubber air hose, understanding air pressure and volume is crucial. Different tasks require varying air flow levels. A pneumatic nail gun may need less pressure than a sandblaster. Knowing the PSI (pounds per square inch) your tools require helps in making the right choice.

Volume is another essential factor. Consider how much air your compressor can deliver. A large volume might be necessary for heavy-duty jobs, while lighter tasks could work with less. Check the diameter of the hose too. A thicker hose allows for more air flow. But, this might make it harder to handle. The balance between flexibility and air flow is not straightforward.

Take time to assess your specific needs. Reflect on your DIY habits and job frequency. Many times, users buy hoses that are either too short or too long. This oversight complicates storage and use. Choosing the right length can make a difference. Ensure your air hose complements your equipment. Pay attention to these details to avoid future frustration.

When selecting a rubber air hose, durability and flexibility are key factors. A durable hose can withstand harsh conditions. It should resist abrasion and won't fray easily. Look for hoses that can handle extreme temperatures. Some hoses might crack in cold weather. Flexible hoses allow for easier maneuvering in tight spaces. They should bend without kinking or tangling.

Additionally, consider the material’s quality. Some lower-quality hoses may appear sturdy but lack real longevity. Testing a hose under pressure can reveal weaknesses. Use a pinch test to check for flexibility. A hose that feels stiff may not perform well in real-world applications. Remember that what works for one task may not work for another.

Not every hose is suitable for every environment. Evaluate your specific needs carefully. Consider how often you’ll use the hose. Frequent use may demand a more robust solution. Pay attention to the hose's weight. Heavier hoses may be more durable but can become cumbersome. It’s essential to balance these factors according to your needs.

Selecting the right rubber air hose starts with understanding its length and size. Industry standards suggest that air hoses typically range from 25 to 100 feet. Longer hoses can limit airflow. A 100-foot hose may decrease pressure and efficiency, especially in high-demand tasks. Consider your workspace layout. Too short? You’ll strain connections. Too long? You risk increased pressure drops.

Sizing is crucial. Common diameters are 1/4”, 3/8”, and 1/2”. A 3/8” diameter hose can supply adequate air for most tools. However, using a smaller diameter might hinder performance. According to a report by the Hose Manufacturers Association, a 1/4” hose could result in a pressure loss of around 27% over longer distances.

Reflect on your requirements. Need mobility? Shorter hoses work best. For fixed stations, a longer hose with a larger diameter may be better. It’s a balancing act. Understanding these dimensions can be tricky. Many users buy based on price rather than specifications. This often leads to frustrations in usage. Evaluate your needs carefully to avoid potential mistakes.